|

TRACTOR

TRACTOR depaneling machine separates the prescored PCB, in a very quick and economic way.

The compact and stable aluminium frame requires a minimum space.

The assembled PCB panel is shoved between the circular blades and is thereby separated.

The circular blades and guides are made of special steel to ensure a long time life.

The hand model is suggested only for small productions and prototype series.

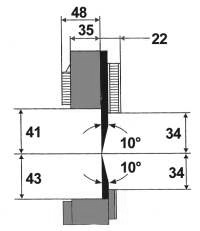

Separation length: up to 350 mm

Thickness of panels: 0.8 – 3.2 mm

Maximum components’s height: 34 – 43 mm

7915.580: TRACTOR – PCB Hand depaneling machine

7915.582: TRACTOR – PCB Motorized depaneling machine 230VAC

7915.583: TRACTOR – PCB Motorized depaneling machine 230VAC / Titan blades

|

|

TRACTOR 2

TRACTOR 2M |

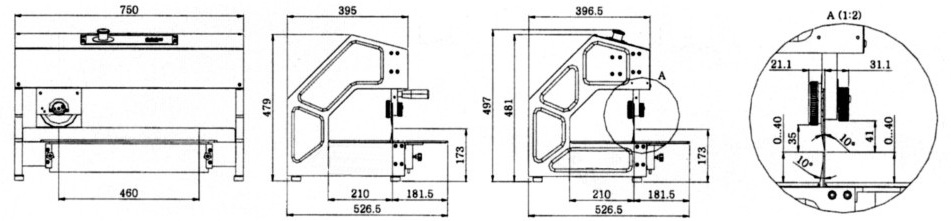

TRACTOR 2

TRACTOR 2 separates both small and large pre-scored PCBs, the maximum separation length is 450mm.

The PCB is placed with its pre-scored groove onto the linear blade and the circular blade is then drawn by hand, or by motor, across the PCB. The clearance between the upper circular blade and the lower linear blade is adjustable

7915.560: TRACTOR 2 – PCB Hand depaneling machine

7915.564: TRACTOR 2M – PCB Motorized depaneling machine 230VAC

|

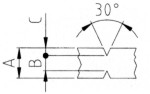

A = 1.0 – 3.2mm |

| B = min 0.3mm / max 0.8mm |

| C = min 0.25mm |

|

|

|

|

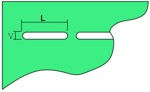

TRACTOR MILL 2

The Tractor Mill 2 depaneling machine mills the routed tabs with the same quality of an automatic system at a lower costs. The key feature of this machine is the easy and quick change of the milling cutter and the interchangeable rail (patented).

This rail is useful to assist the operator to place and drag the circuit until the cut is complete.

The particular shape of the rail avoids any damages to the assembled circuit: if the operator inserts it incorrectly it will not match the eyelet. This rail gives a total protection against possible accidents under safety rules.

This manual depaneling machine has an integrated electric vacuum cleaner system therefore it’s easy to place it in every working area. It has been designed and realized to solve stress

problems, break or tearing out of the PCB’s fi bers that often occur using standard blades or manual tools and that are not tolerated with the increasing complexity and miniaturization.

Aspiration: single phase turbine

Weight: 55Kg

Mains supply: 230V/50Hz

Power: 900W

Depression: -17 kPa (-170 mBar) / -15 kPa (-150 mBar)

PCB thickness: Max 4mm

Slot length (L): Min 11mm

Slot width (V): Standard 1.0 – 3.175mm

Slots / component distance: min. 1mm

PCB material: FR4, CEN, (Al – with optional cutter).

|

|

|

Choose the right mill: 1.5 – 2.5mm

Choose the right rail |

Move the PCB array towards the mill |

The mill removes

the PCB’s tabs |

7915.591: TRACTOR – MILL 2 Depaneling machine with pedal |